Valve Terminology

Applications.

Coaxial valves are used a wide range of applications their use has grown significantly over the past few years as applications require a more precise faster response more compact valve that can offer bi-directional flow control, high flow, long reliable maintenance free 2/2 ON/OFF flow control or 3/2 and manifold diverting flow control for various standard air, gas, argon, nitrogen, helium, oxygen, water, pure water, light and heavy oils, vacuum, aggressive corrosive acidic and alkali media, contaminated and thick glutinous media such as paste like liquids up to 10,000CST.

faster response more compact valve that can offer bi-directional flow control, high flow, long reliable maintenance free 2/2 ON/OFF flow control or 3/2 and manifold diverting flow control for various standard air, gas, argon, nitrogen, helium, oxygen, water, pure water, light and heavy oils, vacuum, aggressive corrosive acidic and alkali media, contaminated and thick glutinous media such as paste like liquids up to 10,000CST.

Valve options make coax valves a very attractive flow control solution for many engineers, such standard options available include normally open function (fail-safe open) , normally closed (fail safe closed), manifold sub base mount manifold systems, open and closed position feed back volt free switches, manual over ride facility, high temperature resistant valves, latching or bi-stable function, valve mounting brackets, aluminium electrical terminal enclosures and degreasing oil/grease free for oxygen applications.

Unlike solenoid operated valves, coaxial valves offer near straight linear uninhibited flow path, they are not restricted by the limits imposed by internal diaphragms and pilot holes, and the media is only in contact with the valves connecting ends, seals and the 316 stainless steel tube, which further reduce corrosion, abrasion, wear and even lime-scale build up from hard water systems.

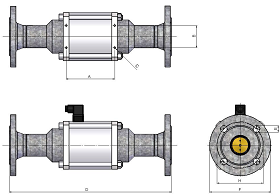

Flanges.

|

Coaxial valves are also available with flanged ends to meet the material and pressure application requirements at hand. Flanges sizes include DN10, DN15, DN20, DN25, DN32, DN40 and DN50 with some coaxial valve manufacturers exceeding DN65 and DN80. Flange types are according to customer application, typical flange options would be PN16, PN40 and PN100, denoting the pressure rating in Bar. Hence a PN16 flange is rated to 16 bar, PN40 to 40 Bar and Pn100 at 100 Bar etc. |

|

Flow Rates.

Flow rates for Kv flow coefficients for coaxial valves depend on the orifice size of the valve and are largely unaffected by the port size or operation. Typically the Kv flow rate factor for most coax valves, can be given as follows.

| Orifice |

2/2 way Kv = m³/Hr |

3/2 way Kv = m³/Hr |

| 10mm | 2.5 | 2.5 |

| 15mm | 4.5 | 5.6 |

| 20mm | 6.8 | 8 |

| 25mm | 11.5 | 11.5 |

| 32mm | 20 | 17.9 |

| 40mm | 38.2 | 34 |

| 50mm | 47.2 | 42 |

Function.

|

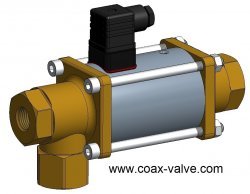

Coaxial valves can be either 2/2 way 2 ports (inlet and outlet) with 2 positions either open or closed or 3/2 way with three ports, one inlet and two outlets with two positions inlet left to outlet 1 right or inlet left to outlet 2 downward. |

|

Materials.

|

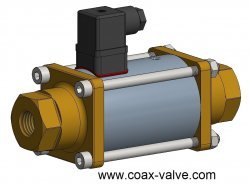

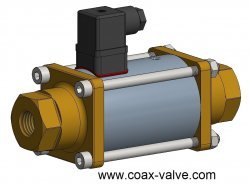

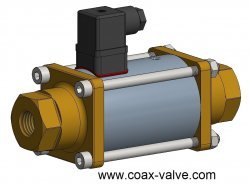

Various materials of construction are available for most models of 2/2 and 3/2 way solenoid or pneumatically driven coaxial valve. Typically users can choose either Steel, Steel Galvanised, Steel Nickel Plated, Brass, Brass nickel plated, V2 304 stainless steel or V4 316 stainless steel material. The internal tube of the valve is always 316 stainless steel, it is only the end caps or port connections that change, which are in contact with the media. The enclosure around the valve body between these end caps is typically galvanised or zinc plated steel. The most common coaxial valves body material is Brass, as seen on the left, on the right we can see a stainless steel version of the same valve. |

|

Modular Systems.

|

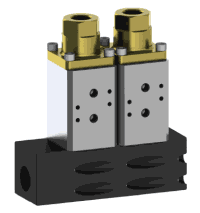

Sub base mounted modular coaxial valves allow for several valves to share a common inlet or outlet, whilst saving space, installation and assembly costs. The picture on the right shows a 2 way sub base mounted coaxial air operated valve and the picture on the left shows a 2 way solenoid actuated valve manifold system. |

|

|

Common manifold mounted valves can be mixed such as including normally open, normally closed, different pipe or orifice sizes and even other process valve all sharing a common manifold system. |

|

Mounting.

Valve mounting can be in every conceivable position or angle and with such a wide range of available standard body and sealing materials and other more specialised options you can start to understand why coaxial valves have become so popular.

Operation.

|

Coaxial valves can be either solenoid operated or pneumatically operated. The coaxial valve on the left is a solenoid operated valve and is activated by electrical signal typically 24vDC or 230vAc 50/60Hz (rectified to 230vdc), this generates in internal electro magnetic field which in turn actuates the valve from open to closed position or visa versa. The coaxial valve on the right is pneumatically operated (actuated by compressed air), by introducing compressed clean air typically 3 to 8 bar the valve internal piston actuates the valve from open to closed position or visa versa. |

|

Power Consumption.

Electrically actuated coax valves are typically either 24vDC or 230vAC retified by DIN43650A connector with bridge rectifier, as coaxial valves cannot handle AC 50/60Hz voltages directly as they do not have a shading ring. Other voltages are also available, allbeit with some additional cost, such as 24vAC, 48vAC, 48vDC, 110vAC and 110vDC. The bigger the diameter of the axial tube known as the orifice, the bigger the forces required to move it and hence the electrical power consumption of the coil increases. Please find below typical power requirments for coaxial solenoid controlled valves.

| 2/2 way | 3/2 way | ||||

|

Orifice mm |

Watts 24vDC | Watts 230vAC | Orifice | Watts 24vDC | Watts 230vAC |

| 10 | 35 | 41 | 10 | 35 | 41 |

| 15 | 40 | 45 | 15 | 40 | 45 |

| 20 | 45 | 53 | 20 | 45 | 53 |

| 25 | 60 | 68 | 25 | 60 | 68 |

| 32 | 73 | 76 | 32 | 73 | 76 |

| 40 | 73 | 91 | 40 | 73 | 90 |

| 50 | 73 | 91 | 50 | 73 | 90 |

Pressures.

|

Pressures ranges from vacuum to 10, 16, 20, 40, 64, 100, 120, 160, 200 up to 400 bar depending on the model, method of operation, valve function and orifice size of choice. Typically each model or series of coax valve will have a predetermined pressure range and function, for example the 2/2 way coax solenoid valve 0 to 40 bar valve as seen on the left typically has options for body material, port size, orifice size, function, seal type and option for control voltage etc, where a coax 3/2 way coax pneumatic actuated valve 0 to 64 bar as seen on the right would have options for body material, port size, orifice size, function, seal type and option for namur mounted solenoid controller. |

|

Seals.

Coaxial valves have both statis (none moving) and dynamic (moving) seals. The most common coax valve seal is FKM which is commonly know as Viton which is a registered trade mark of Dupont. Oher coax valve seals include NBR Nitrile Buna Rubber, EPDM Ethylene Propylene Diene Monomer and also PTFE Polytetrafluoroethylene also know as Teflon.

The combination of strong performance and construction characteristics designed to meet a wide range flow rate and design applications for many industries.

Threads.

|

Coaxial valves commonly have threaded female pipe connections. Thread types are typically BSPP thread British Standard Pipe Parallel, for the UK and European markets or NPT female thread National Pipe Taper thread for the American and Canadian markets in the USA. Thread sizes include 1/8, 1/4, 3/8, 1/2, 3/4, 1, 11/4, 11/2 or 2". |

|

Weight.

Coaxial valves across most valve manufacturers will have similar weights, the design and structure of the valves are almost identical and even material diffferences will only have a very small affect.

| 2/2 way | 3/2 way | ||||

|

Orifice mm |

Port | Kg | Orifice | Port | Kg |

| 10 | 1/4, 3/8, 1/2 | 1.7 | 10 | 1/4, 3/8, 1/2 | 1.9 |

| 15 | 3/8, 1/2, 3/4 | 3.6 | 15 | 3/8, 1/2, 3/4 | 4 |

| 20 | 1/2, 3/4, 1 | 5.4 | 20 | 1/2, 3/4, 1 | 6 |

| 25 | 3/4, 1, 11/4 | 7.1 | 25 | 3/4, 1, 11/4 | 7.5 |

| 32 | 1, 11/4, 11/2 | 12.6 | 32 | 1, 11/4, 11/2 | 13.4 |

| 40 | 11/2 | 18.3 | 40 | 11/2 | 18.7 |

| 50 | 2 | 18.3 | 50 | 2 | 18.5 |

You can read more about the four main types of coaxial valves sections.