Special Solutions

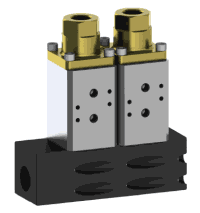

Some manufacturers of coaxial valves can also offer custom-made solutions to meet very specific application requirements. This is actually quite a sim ple exercise for coax valve suppliers to achieve as only the block that needs to be designed and manufactured, the rest of the valve parts will probably be standard production parts that can simply bolt into place and coaxial valves can be mounted in any position. The picture on the right demonstrates how this is easily achieved without undue cost or time. Here a customer required four separate 2/2 way solenoid operated coax valves to work from the smallest possible most compact manifold block. The dimensions of the block mounting are a fixed existing technical parameter the solution was simply designed to incorporate existing production parts to suit application requirements, i.e. four separate 2/2 way controlled high pressure liquid media outlets with on/off control, 2 coaxial valves mounted vertically, and two additional coaxial valves mounted at each end of the block.

ple exercise for coax valve suppliers to achieve as only the block that needs to be designed and manufactured, the rest of the valve parts will probably be standard production parts that can simply bolt into place and coaxial valves can be mounted in any position. The picture on the right demonstrates how this is easily achieved without undue cost or time. Here a customer required four separate 2/2 way solenoid operated coax valves to work from the smallest possible most compact manifold block. The dimensions of the block mounting are a fixed existing technical parameter the solution was simply designed to incorporate existing production parts to suit application requirements, i.e. four separate 2/2 way controlled high pressure liquid media outlets with on/off control, 2 coaxial valves mounted vertically, and two additional coaxial valves mounted at each end of the block.

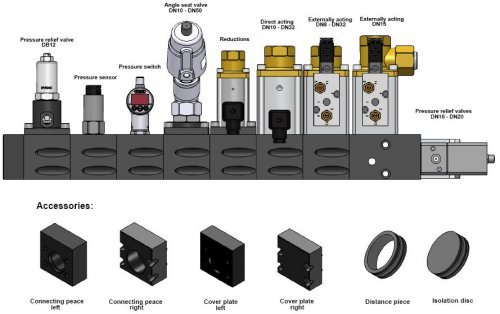

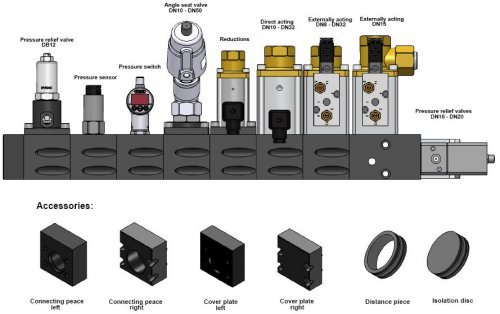

Coaxial valve modular system.

Coaxial Valve Technology – Leading the way forward.

Connexion Developments Ltd, in collaboration with RSG Regel - und Steuergeräte GmbH, is pleased to announce a significant achievement in the realm of custom manifold design, specifically in the coaxial valve domain.

Connexion Developments Ltd, in collaboration with RSG Regel - und Steuergeräte GmbH, is pleased to announce a significant achievement in the realm of custom manifold design, specifically in the coaxial valve domain.

Initially employing standard 2/2 way coaxial valves for the construction of high-pressure 40 Bar fluid control systems, our client sought a more tailored solution for their manifold system.

Recognizing the limitations of the existing approach, we introduced the RSG  270X modular system, which proved to be an optimal choice. This modular system offers versatility through a range of combinations and full customization capabilities, accommodating pressure control valves and monitoring devices.

270X modular system, which proved to be an optimal choice. This modular system offers versatility through a range of combinations and full customization capabilities, accommodating pressure control valves and monitoring devices.

The seamless integration of the RSG 270X modular system paved the way for the development of a fully customized 3D- printed plastic valve manifold system tailored to the client's specifications. This bespoke solution, meticulously crafted to meet both dimensional and functional requirements, was delivered within a commendable 30-day timeframe in September 2022.

The seamless integration of the RSG 270X modular system paved the way for the development of a fully customized 3D- printed plastic valve manifold system tailored to the client's specifications. This bespoke solution, meticulously crafted to meet both dimensional and functional requirements, was delivered within a commendable 30-day timeframe in September 2022.

Following rigorous functional tests and evaluations, the successful validation in May 2023 led to the awarding of an 18-month contract. In July, a minor, non-critical modification to the valve's exterior was seamlessly incorporated into the design.

Despite this modification, the delivery timeline only experienced a minimal extension of three weeks. Consequently, the complete delivery was expedited, and the project was successfully concluded in early November 2023.

sub base mounted to a single manifold are easily achievable on the same manifold. The picture on the right shows air operated 2/2 way coaxial valve with 5/2 pilot controller mounted to a manifold system with three angle seat piston valves which are also compressed air pilot controlled. This coaxial valve modular system has almost limitless potential with so many valve 2/2 and 3/2 way coax model options offering compact and high pressure control for even most most arduous media applications.

sub base mounted to a single manifold are easily achievable on the same manifold. The picture on the right shows air operated 2/2 way coaxial valve with 5/2 pilot controller mounted to a manifold system with three angle seat piston valves which are also compressed air pilot controlled. This coaxial valve modular system has almost limitless potential with so many valve 2/2 and 3/2 way coax model options offering compact and high pressure control for even most most arduous media applications. together to create a single shared manifold system. This modular technology has become a key component for process control systems where two or more coaxial solenoid valves can be used share either a common inlet or common outlet without the need for additional pipework and fittings, reducing space and increasing functionality.

together to create a single shared manifold system. This modular technology has become a key component for process control systems where two or more coaxial solenoid valves can be used share either a common inlet or common outlet without the need for additional pipework and fittings, reducing space and increasing functionality. shared manifold modular system. This sub base mounted coaxial valve technology has evolved rapidly due to increasing demand so now air actuated coaxial valve users can now simply assemble or modify existing modules on site offering a common inlet or outlet port for all their air driven coax valves. In most process applications compressed air supply and control is the preferred choice reducing the need for high power electrical systems and reducing the potential of sparks, electrical failures and especially hazardous area applications for potentially explosive gas and dust environments.

shared manifold modular system. This sub base mounted coaxial valve technology has evolved rapidly due to increasing demand so now air actuated coaxial valve users can now simply assemble or modify existing modules on site offering a common inlet or outlet port for all their air driven coax valves. In most process applications compressed air supply and control is the preferred choice reducing the need for high power electrical systems and reducing the potential of sparks, electrical failures and especially hazardous area applications for potentially explosive gas and dust environments.  ple exercise for coax valve suppliers to achieve as only the block that needs to be designed and manufactured, the rest of the valve parts will probably be standard production parts that can simply bolt into place and coaxial valves can be mounted in any position. The picture on the right demonstrates how this is easily achieved without undue cost or time. Here a customer required four separate 2/2 way solenoid operated coax valves to work from the smallest possible most compact manifold block. The dimensions of the block mounting are a fixed existing technical parameter the solution was simply designed to incorporate existing production parts to suit application requirements, i.e. four separate 2/2 way controlled high pressure liquid media outlets with on/off control, 2 coaxial valves mounted vertically, and two additional coaxial valves mounted at each end of the block.

ple exercise for coax valve suppliers to achieve as only the block that needs to be designed and manufactured, the rest of the valve parts will probably be standard production parts that can simply bolt into place and coaxial valves can be mounted in any position. The picture on the right demonstrates how this is easily achieved without undue cost or time. Here a customer required four separate 2/2 way solenoid operated coax valves to work from the smallest possible most compact manifold block. The dimensions of the block mounting are a fixed existing technical parameter the solution was simply designed to incorporate existing production parts to suit application requirements, i.e. four separate 2/2 way controlled high pressure liquid media outlets with on/off control, 2 coaxial valves mounted vertically, and two additional coaxial valves mounted at each end of the block.

Connexion Developments Ltd, in collaboration with RSG Regel - und Steuergeräte GmbH, is pleased to announce a significant achievement in the realm of custom manifold design, specifically in the coaxial valve domain.

Connexion Developments Ltd, in collaboration with RSG Regel - und Steuergeräte GmbH, is pleased to announce a significant achievement in the realm of custom manifold design, specifically in the coaxial valve domain. 270X modular system, which proved to be an optimal choice. This modular system offers versatility through a range of combinations and full customization capabilities, accommodating pressure control valves and monitoring devices.

270X modular system, which proved to be an optimal choice. This modular system offers versatility through a range of combinations and full customization capabilities, accommodating pressure control valves and monitoring devices. The seamless integration of the RSG 270X modular system paved the way for the development of a fully customized 3D- printed plastic valve manifold system tailored to the client's specifications. This bespoke solution, meticulously crafted to meet both dimensional and functional requirements, was delivered within a commendable 30-day timeframe in September 2022.

The seamless integration of the RSG 270X modular system paved the way for the development of a fully customized 3D- printed plastic valve manifold system tailored to the client's specifications. This bespoke solution, meticulously crafted to meet both dimensional and functional requirements, was delivered within a commendable 30-day timeframe in September 2022.